Howo 10 Wheeler 371 25ton Dump Truck

- HOWO

- Shandong

- 35 days

- 150 sets

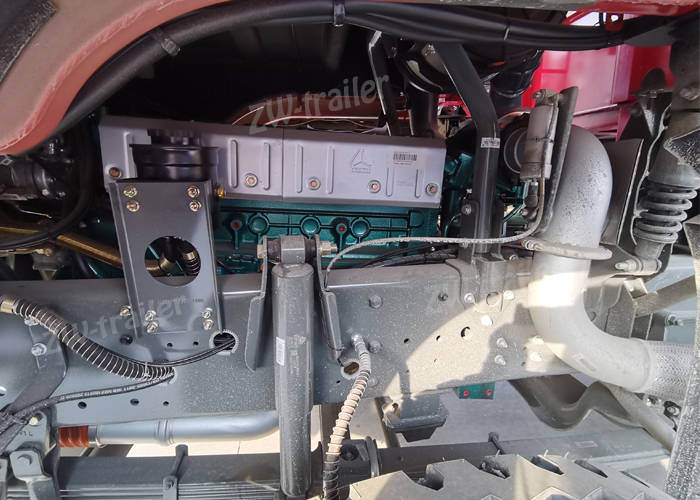

Howo 10 wheeler dump truck is equipped with an automatic dumping device in the carriage. Howo 10 wheeler dump truck is composed of automobile chassis, hydraulic lifting mechanism, power take-off device and cargo compartment. In civil engineering, Howo 10 wheeler dump truck is often combined with excavators, loaders, belt conveyors, etc. to form a loading, transporting, and unloading production line for the loading, unloading and transportation of earthwork, sand, and loose materials. Because the loading carriage can automatically tilt to discharge at a certain angle, Howo 10 wheeler dump truck greatly saves the unloading time and labor, shortens the transportation cycle, improves production efficiency, reduces transportation costs, and indicates the loading volume.

Howo 25 ton dump truck is a commonly used transportation machine. The structure of the engine, chassis and cab is the same as that of general trucks. The carriage can be tilted backwards or sideways. The piston rod movement is controlled by the control system. Later tilting is more common. Push the piston rod to tilt the cabin.

Howo 25 ton dump truck is mainly composed of hydraulic dumping mechanism, carriage, frame and accessories. Among them, the modification manufacturers of hydraulic dumping mechanism and carriage structure are different. The following describes the structure of dump truck according to two aspects of the type of carriage and lifting mechanism.

According to different users, the type of car junction mechanism can be divided into: ordinary rectangular car and mine bucket car. Ordinary rectangular cars are used for bulk cargo transportation. The rear panel is equipped with an automatic opening and closing mechanism to ensure the smooth discharge of the goods. The thickness of the ordinary rectangular carriage is: front panel 4 ~ 6, side panel 4 ~ 8, rear panel 5 ~ 8, bottom panel 6 ~ 12. Mine bucket cars are suitable for the transportation of large-grained goods such as large stones.

Considering the impact and collision of the cargo, the design shape of the mining bucket car is more complicated and the material used is thicker. For example, the standard configuration thickness of the mining bucket car is: front 6 sides, 6 bottom 10, and some models are welded with some angle steel on the bottom plate to increase the rigidity and impact resistance of the Howo 25 ton dump truck. The lifting mechanism is the core of the Howo 371 dump truck, and is the primary indicator to judge the quality of the dump truck. The types of lifting mechanisms are currently common in China: F-type tripod enlarged lifting mechanism, T-type tripod enlarged lifting mechanism, double-cylinder lifting, front top lifting and double-sided rollover. The tripod magnifying lifting mechanism is one of the most commonly used lifting methods in China. Howo 371 dump truck is suitable for load capacity of 8 to 40 tons and carriage length of 4.4 to 6 meters.

The advantages are mature structure, stable lifting, and low cost; the disadvantage is that the closing height of the floor of the carriage and the upper plane of the main frame is relatively large. The double-cylinder lifting method is mostly used in 6X4 dump trucks. A multi-stage cylinder (generally 3 to 4 stages) is installed on each side of the front of the second bridge. The fulcrum of the hydraulic cylinder directly acts on the floor of the car.

The advantage of double-cylinder lifting is that the closing height of the carriage floor and the plane on the main frame is small; the disadvantage is that the hydraulic system is difficult to ensure the synchronization of the two hydraulic cylinders, the lifting stability is poor, and the overall rigidity of the carriage floor is higher.

The front jacking method of Howo 371 dump truck has a simple structure, the closing height of the floor of the carriage and the plane of the main frame can be small, the stability of the whole vehicle is good, the pressure of the hydraulic system is small, but the front multistage cylinder has a large stroke and high cost.

Double-sided rollover hydraulic cylinder has better force and smaller stroke, which can achieve double-sided rollover; but the hydraulic pipeline is more complicated, and the occurrence rate of accidents of rollover is higher.